No.122 [2023] of Ministry of Industry and Information Technology

The competent departments of industry and information technology of all provinces, autonomous regions, municipalities directly under the Central Government and cities under separate state planning, Xinjiang Production and Construction Corps, relevant industry associations, enterprises and institutions:

The "Implementation Opinions on the Construction and Application of Manufacturing Technology Innovation System" are hereby printed and distributed to you, please conscientiously implement it according to the actual situation.

Ministry of Industry and Information Technology

August 15, 2023

Suggestions on the construction and application of technological innovation system in manufacturing industry

In order to implement the decision-making arrangements of the CPC Central Committee and the State Council on promoting the high-quality development of the manufacturing industry, comprehensively and accurately grasp the status quo of industrial technology, effectively carry out technical research, transformation of achievements and popularization of advanced and applicable technologies, implement the construction and application of the manufacturing technology innovation system (hereinafter referred to as the technical system), optimize the allocation of innovative resources, support the construction of industrial basic capacity, create new advantages in systematic competition, realize the self-reliance of high-level industrial science and technology, and accelerate the process of new industrialization, these implementation opinions are formulated.

(A) the guiding ideology

Guided by the Supreme Leader’s Socialism with Chinese characteristics Thought in the New Era, we should thoroughly implement the spirit of the 20th Party Congress, base ourselves on the new development stage, implement the new development concept completely, accurately and comprehensively, build a new development pattern, adhere to the system concept, and build a systematic and systematic system around the key technology supply lines of typical manufacturing products, bill of materials, key production enterprises and other technical support lines of research and development design tools, manufacturing equipment, standards, quality, management services and key software. Relying on the technical system, identify the shortcomings and strengths of industrial technology, fully support industrial scientific and technological innovation, promote the deep integration of innovation chain, industrial chain, capital chain and talent chain, promote the upgrading of industrial base and the modernization of industrial chain, and strongly support the construction of manufacturing power, network power and digital China.

(2) Basic principles

Systematic thinking and scientific analysis.Focusing on the life cycle of typical products in key industries, we will comprehensively clarify the development status of the technology system, accurately locate the shortcomings and advantages of technology, and carry out key core technology research and advanced technology promotion.

Enterprise-led, multi-party linkage.Strengthen the linkage between supply and demand, fully mobilize the enthusiasm of leading enterprises, give play to the role of various innovation platforms, deepen the cooperation between the upstream and downstream of the industrial chain and Industry-University-Research, and promote the construction and popularization of the technology system.

Central and local cooperation, classified implementation.Facing the urgent need of national strategic development, we should focus on key industries and typical products to build a technical system. Fully mobilize the enthusiasm of local governments and promote the construction of industrial technology system with advantages and characteristics according to local conditions.

Dynamic monitoring and regular updating.Adapt to the new situation and new requirements, carry out dynamic monitoring of the technical system, and regularly update the technical system, so as to provide support for dynamically adjusting the direction of technical research, preventing risks in the industrial chain and supply chain, and formulating corresponding measures.

(III) Work objectives

By 2025, a set of scientific, applicable, standard and standardized construction methods for manufacturing technology innovation system will be formed, and a technology system covering typical products of key industries in manufacturing industry will be basically established, and a short-board technology research library, a long-board technology reserve library and an advanced and applicable technology promotion library will be established by classification and grading. Through effective application, the effectiveness of the technical system has initially appeared, industrial scientific and technological research has been more comprehensive and accurate, the industrialization of scientific and technological achievements and the promotion of new technologies have been more effective, and the construction of industrial basic capabilities such as standards, quality and key software has been significantly enhanced; It has achieved remarkable results in guiding local governments to strengthen the chain of industrial chain and develop regional industrial clusters; Guide enterprises to continuously improve the level of supply chain risk management, and continuously optimize the enterprise technology research and development system.

By 2027, an advanced manufacturing technology innovation system will be built, and a network of technology systems with horizontal coordination and vertical connectivity will be formed in an all-round way. The technology system is comprehensively applied to tackling key problems in industrial science and technology, transforming achievements and popularizing new technologies, effectively guiding the technological innovation and industrial agglomeration development of local manufacturing industries, effectively guiding enterprises to establish advanced R&D systems and scientific supply chain management systems, and providing important support for the self-reliance and high-quality development of manufacturing industries.

Second,Technical system construction

Technical system“1295”To summarize, that is, according to the product production process or product components.1 setThe interlocking evaluation and analysis framework focuses on the supply and support of industrial technology.Article 2Main line, forming key technologies, materials, enterprises, R&D design, manufacturing equipment, quality, standards, management services and key software.Nine sheetsList, according to the technology maturity and manufacturing maturity model, compare the gap between domestic and foreign countries, and formfiveEvaluation grade.

(1) Composition of technical system

1. Key technologies

Combing and analyzing the main technologies contained in typical products, including main characteristic indexes, domestic and international technological development situation, technological development gap, etc., comprehensively reflecting the technological development situation and forming a list of key technologies.

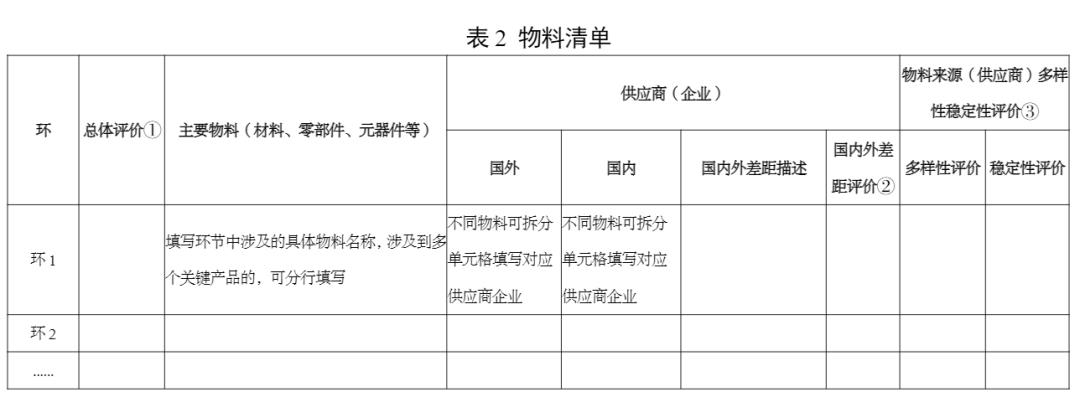

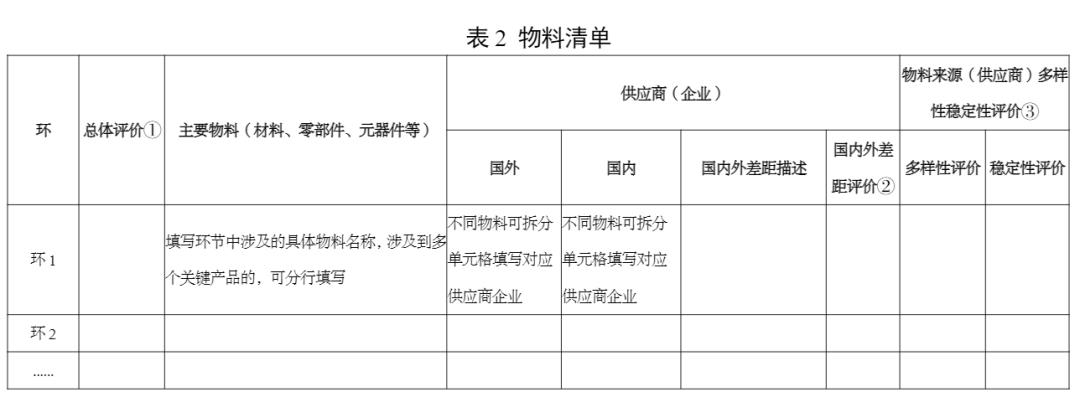

2. Materials

Combing and analyzing the key materials, components or spare parts involved in the key technologies of typical products, including the comparison of main materials at home and abroad, the diversification and stability of material sources, etc., comprehensively reflecting the material situation in the supply chain and forming a list of key materials.

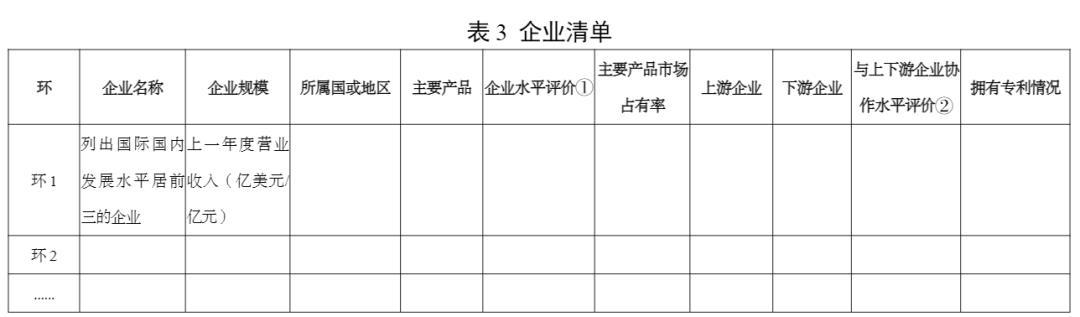

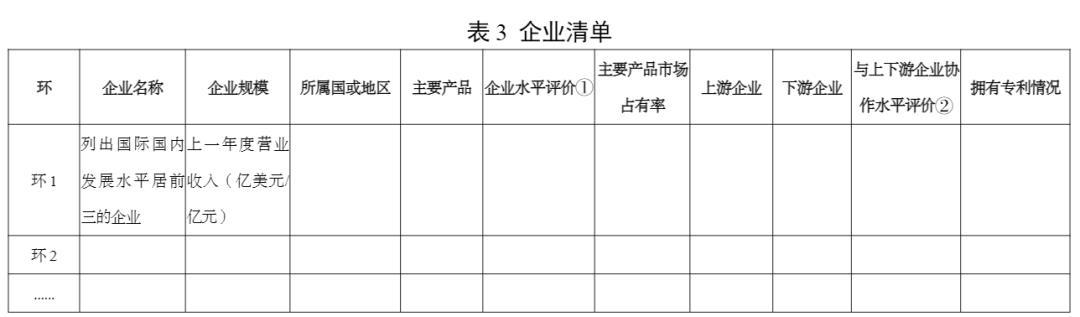

3. Enterprise

Combing and analyzing the main production enterprises of key materials of typical products, including product market.Market share, enterprise scale, enterprise distribution, upstream and downstream cooperation and patents, etc., fully reflect the development level of production enterprises and form a list of key production enterprises.

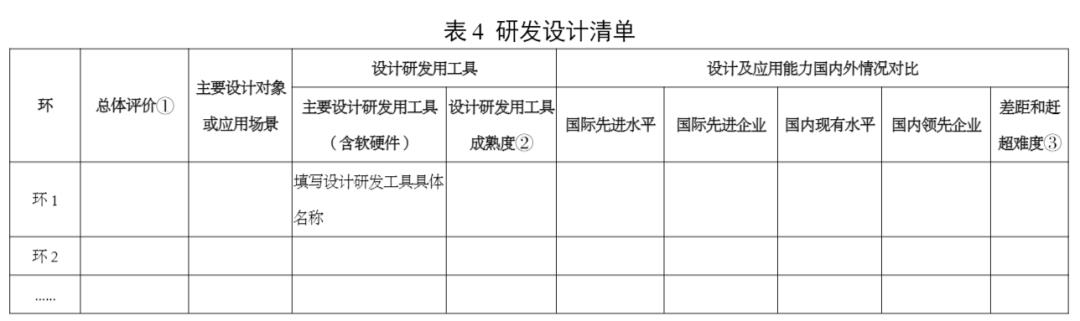

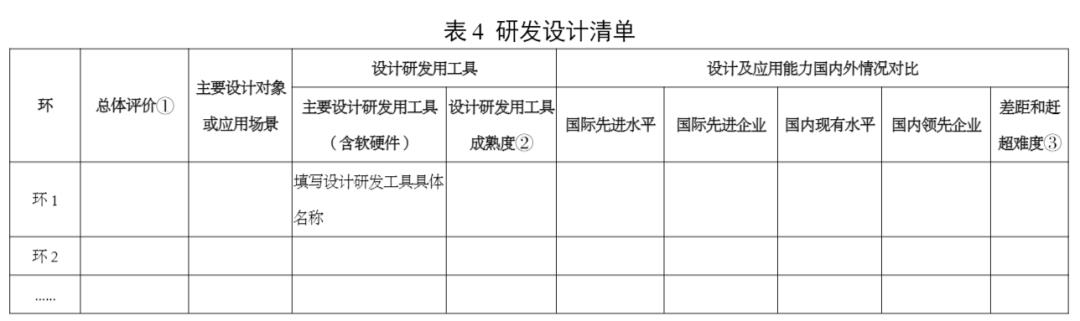

4. Research and development design

Combing and analyzing the main software and hardware tools used in the process of R&D and design of typical products, including R&D and design enterprises at home and abroad, R&D and design ability and tool application level, etc., comprehensively reflecting the development status of R&D and design tools, and forming a list of typical product R&D and design tools.

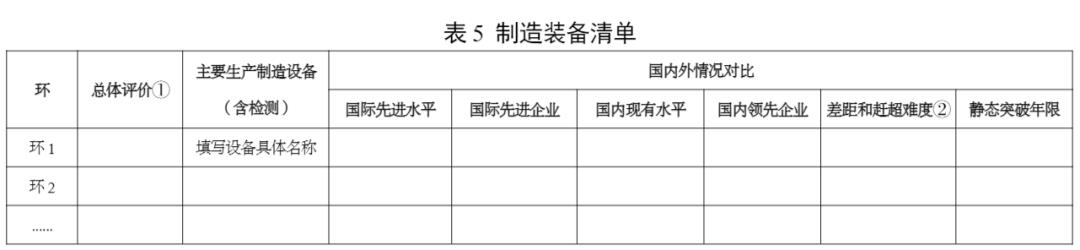

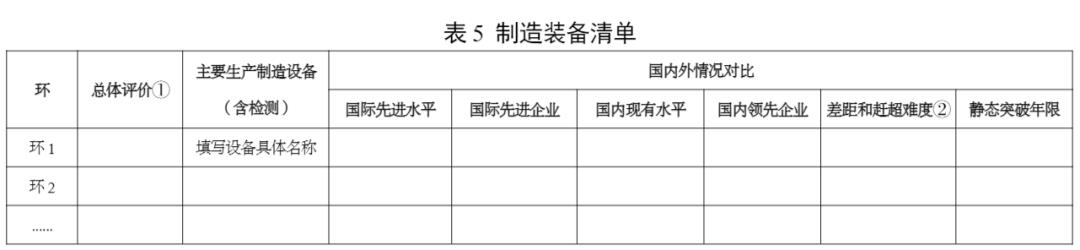

Step 5 make equipment

Combing and analyzing the manufacturing equipment used in the production process of typical products, including the production level, production enterprises, market application and development gap of manufacturing equipment at home and abroad, comprehensively reflecting the development status of manufacturing equipment and forming a list of main manufacturing equipment.

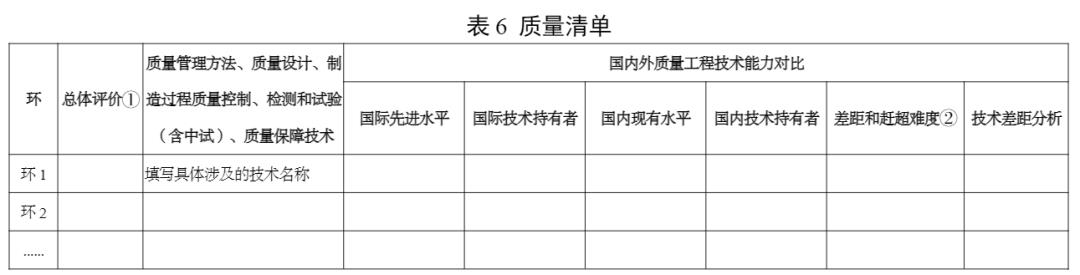

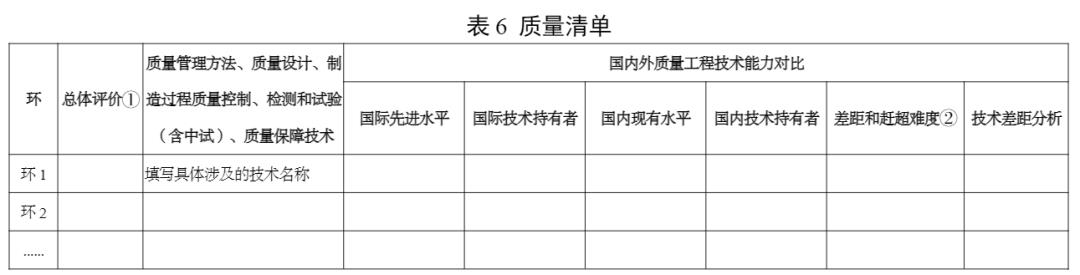

6. Quality

Combing and analyzing the quality management and control involved in the management process of typical products, including quality engineering technology, testing equipment and instruments, quality tool software, etc. used in the production process, comprehensively reflecting the quality status of typical products and forming a quality list.

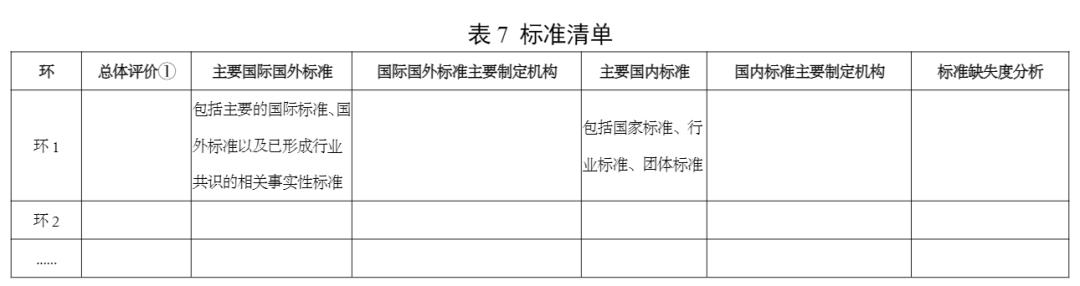

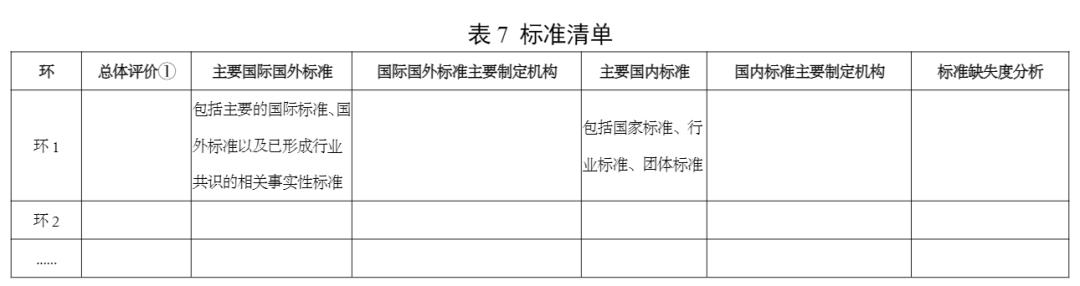

7. Standards

Sort out and analyze the main standards involved in the life cycle process of typical products, including all kinds of standards, main standard-making institutions, and the lack of standards, etc., comprehensively reflect the construction and implementation of the standard system, and form a list of main standards.

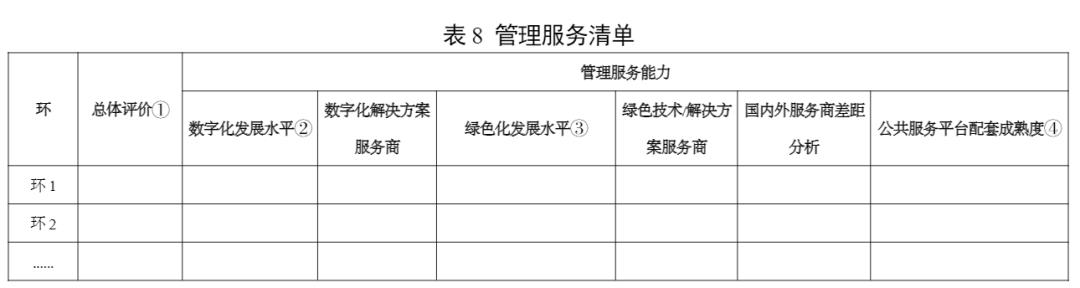

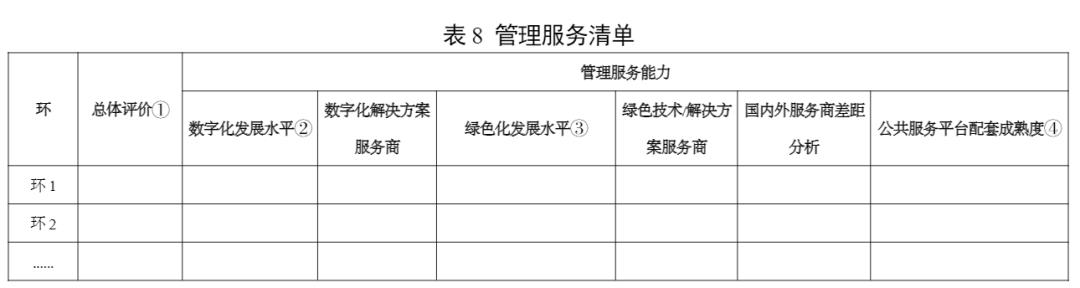

8. Management services

Combing and analyzing the digital and green management services required in the production process of typical products, including domestic and foreign digital and green solution service providers, the maturity of public service platforms and the gap between domestic and foreign service capabilities, etc., comprehensively reflecting the development level of management services and forming a list of management services.

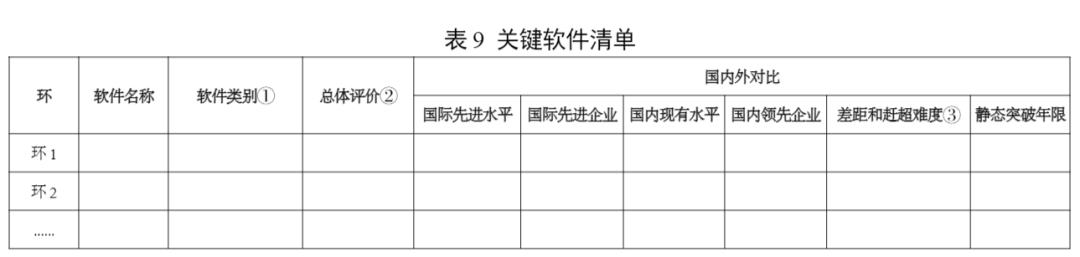

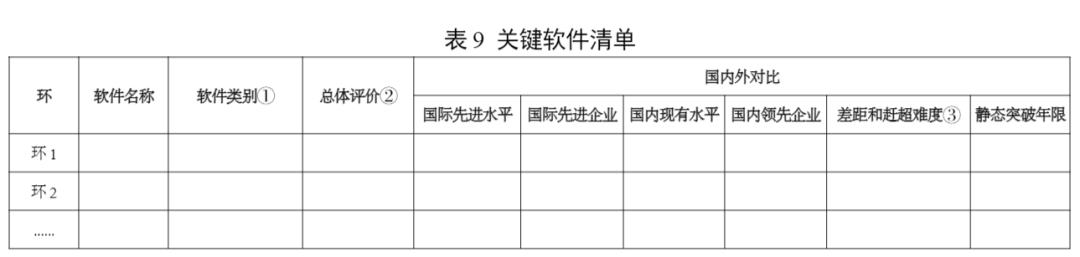

9. Key software

Combing and analyzing the key software used in the production and application of typical products, such as business management, production control and basic general software, including the main service providers of key software at home and abroad, software application level and development gap, etc., comprehensively reflecting the development status of key software and forming a list of key software.

(2) Evaluation grade of technical system

The evaluation of technology system includes 9 aspects: overall evaluation and specific evaluation. Five grades are set according to the maturity of technology and manufacturing industry, which fully reflect the development level, basic commonality, gap and catching-up difficulty of key technologies in the industrial chain (according to the maturity of technology, key technologies are divided into three categories: technologies without independent ability, technologies that need industrialization and mature technologies that can be widely popularized). The gap between materials at home and abroad and the stability of supplier source diversity; The overall level of the enterprise and the level of upstream and downstream cooperation; Maturity, gap and catching-up difficulty of R&D design tools; The gap between manufacturing equipment and quality engineering technology and the difficulty of catching up; Digital development level of management and public service, green development level, supporting maturity of public service platform, etc.

Third,Evaluation, update and expansion of technical system

(1) Scientific assessment

The Ministry of Industry and Information Technology conducts a comprehensive evaluation according to the actual situation of comprehensiveness, timeliness, accuracy and advancement of the technical system construction. Timely evaluate the application of technical system in supporting scientific and technological research, formulating project guidelines, project process management, appraisal and acceptance evaluation. The local competent department of industry and information technology shall, according to the needs, evaluate the construction and application of the technical system in terms of scientific and technological research support, investment attraction influence, contribution of social and economic benefits, and enterprise capacity building.

(2) Dynamic update

Establish a technical system information monitoring service platform, dynamically monitor the technical system, and update the technical system in time according to the technical development, product iteration and industry application. At the same time, dynamically adjust the short-board technical research library, long-board technical reserve library and advanced and applicable technology promotion library, regularly compile technical system diagnosis and analysis reports, and verify the effectiveness of technical system construction according to the monitoring results. The local competent department of industry and information technology shall dynamically update the construction of the local technical system according to the technical development and industrial layout requirements.

(3) Reasonable expansion

In view of the breakpoints and sticking points involved in typical products of key industries, we adopt the method of "peeling onions" by analogy reasoning, and further explore the problems and research and evaluation by using technical system methods, and gradually improve and form an interlocking and in-depth technical system architecture, so as to comprehensively identify and accurately locate the breakpoints and find out the power points for tackling key problems and promoting technology. At the same time, by combing and clarifying the correlation between different industrial chains, we can concise the basic common problems and further form a technical network system that can exchange information and cooperate.

Fourth,Application of technical system

(A) support key core technology research

Support the formulation of scientific and technological research project guidelines and accurately determine key research projects. According to the shortcomings in the technical system, according to the technical evaluation level, around the core technology, manufacturing equipment, quality and key software involved in typical products, sort out the key technical problems, establish the key core technology research catalogue, so as to be comprehensive and accurate, and prevent omissions and repeated projects. Connect with key R&D plans for scientific and technological innovation and major scientific and technological projects, and effectively support industrial base reconstruction projects and major technical and equipment research projects.

(2) Supporting the industrialization of scientific and technological achievements

According to the technical system and technical evaluation level, determine the list of achievements, carry out industrialization work by classification, strengthen the docking with existing carriers around typical products in key industries, and avoid invalid transformation of achievements. Adhere to the enterprise as the main body, Industry-University-Research coordination, give full play to the advantages of the system and mechanism, and form a joint force of industrialization. Relying on industrial common technology platforms such as manufacturing innovation centers, key laboratories, and quality evaluation laboratories, we will strengthen the capacity building of intermediate tests and comprehensive support services for industrialization.

(3) Support the popularization of advanced and applicable technologies.

Apply the technical system, accurately identify the advantages of long board, and form the promotion catalogue of advanced and applicable technologies. Carry out technology promotion according to the characteristics of the industry, realize the technological progress of the whole industry, effectively improve quality and efficiency, accelerate the digital transformation, and realize high-end, intelligent and green development. Give full play to the role of industry organizations and professional institutions, make good use of standards, certification and other tools, strengthen the docking of supply and demand, match and share resources, form a work linkage, and continuously improve the quality and efficiency of technology promotion.

(D) Support the construction of industrial technology infrastructure.

According to the technical system, we will systematically sort out the basic capabilities of industrial technology, support the formulation and promotion of standards, and give full play to the leading role of standards. Support the construction of quality inspection and test capacity, and continuously improve the quality, technology and management level of the industry. Support the construction of measurement capacity and continuously improve the accuracy and effectiveness of measurement. Support the construction of scientific and technological achievements, industrial information and intellectual property rights, and provide a strong guarantee for industrial technological progress and high-quality development.

(V) Supporting the development of regional industries

According to the regional industrial technology system, comprehensively reflect the industrial development in the region, accurately carry out the chain reinforcement and strong chain of the industrial chain, optimize the regional industrial layout and innovative resource allocation, carry out targeted investment attraction, cultivate and introduce high-quality enterprises, and form a high-level innovative enterprise echelon. Coordinate the industrial basic capacity in the region to provide effective support for optimizing the investment environment, consolidating the foundation of industrial development, and deepening the industrial division of labor and agglomeration development.

(six) support enterprise technology research and development and supply chain management.

According to its own technology system, enterprises can accurately evaluate the technology R&D and supply chain management, identify the technical advantages and shortcomings, optimize the R&D management system, effectively carry out technology R&D, promote technological progress and maintain competitive advantage. Strengthen supply chain management, continuously optimize qualified materials and suppliers, establish and improve risk early warning and prevention and control mechanisms, coordinate safety, efficiency and cost, and continuously improve the supply chain management system.

(A) to strengthen overall coordination

The Ministry of Industry and Information Technology strengthens the organization and leadership of the technical system construction, strengthens the connection between the technical system and industrial policies and regulations, gives full play to the role of leading enterprises, and coordinates the forces of industry associations, industrial alliances, universities, research institutes and professional think tanks to form a joint effort to promote the deep integration of innovation chain with industrial chain, capital chain and talent chain. Establish a working mechanism of coordination and multi-party linkage between the central and local governments, and the local competent departments of industry and information technology organize the construction and application of the technical system in the region.

(2) Strengthening basic security.

Strengthen the supporting capabilities of industrial technology basic service platforms, key laboratories and standardized technical institutions, give full play to technological advantages, and effectively support the construction and application of technical systems. For industries, localities and enterprises, carry out multi-level technical system construction methods and application training. Relying on the information monitoring service platform of technical system, it provides support and services for the construction, evaluation, update, expansion and application of technical system.

(C) Pay attention to data security

Improve the awareness of safety precautions for data related to the technical system, continuously improve the ability of data security, establish an advanced data security management mechanism, conduct classified management according to regulations, and standardize data collection, update and analysis. Regularly carry out data risk assessment on technical system construction and application, and conduct security monitoring on relevant service platforms to prevent data security risks.

(4) Promoting open cooperation.

Strengthen cross-regional, cross-industry and inter-departmental technology systems to build, share, exchange and cooperate, and promote deep cooperation between upstream and downstream of the industrial chain and complementary advantages of innovative resources. Give full play to the role of the technical system, strengthen international technical exchanges and cooperation, carry out accurate docking in technology, materials, suppliers, industrial basic capabilities and services, continue to strengthen soft connectivity in markets and rules, steadily expand institutional openness such as standards, and support the construction of new development patterns.

Attachment:

Framework of manufacturing technology innovation system

Instructions for filling in the form:

1. The division of links (referred to as "rings" for short) in each table should be unified, which can be divided according to the characteristics of equipment or products, components (such as discrete manufacturing) or manufacturing processes (such as process manufacturing). At the same time, the division of rings needs to be clearly explained, which can include reference standards and references.

2. The overall evaluation involved in the table needs to be analyzed in combination with specific notes.

3. The table should be as detailed as possible to a number of specific technologies, analyze their specific technical indicators, and fill in relevant contents respectively.

4. According to the industry attribute, the form that is not applicable needs to be filled in as "Not involved".

5. Table 4 mainly focuses on the tools used in R&D design, including software and hardware. Table 9 The list of key software refers to the software used in the manufacturing process, including R&D design, business management, production control and basic general software. If the software itself is an important component of the product/equipment, it should be listed as "ring" separately. If the R&D and design software in Table 4 is involved in Table 9, it can be indicated in Table 4.

Note:

① There are 1-5★, and the more★, the higher the overall level. Among them, one ★ belongs to the field of "stuck neck", which is highly dependent on the outside world in terms of products and technology, and its self-sufficiency rate is very low. Two ★ means that technology belongs to the field of "stuck neck", and it is externally dependent on products and technologies, and the technology and products as a whole are not competitive and have weak self-sufficiency ability. 3 ★ means that the independent technology and products are in the "usable" stage, and some technologies and products in the link have certain competitiveness at home and abroad, and the self-sufficiency rate is at a medium level. 4 ★ means that the independent technology and products are in the "easy to use" stage, and some technologies in the link have strong international competitiveness and high self-sufficiency rate. Five ★ represents that the independent technology and products in the link are in the "easy to use" stage, with strong international competitiveness, leading domestic technology level and high self-sufficiency rate.

② It is divided into 1-5 grades, and the higher the number, the higher the level of technological development. Among them, the level 1 representative has weak technical ability and is seriously subject to people. Level-2 represents weak self-owned technical ability, and key technologies are subject to people. Level 3 represents a certain breakthrough in its own technology and keeps pace with the international leading level. The key technologies of Level 4 Representative are relatively mature, and some of them have reached the international advanced level. Level 5 represents the establishment and perfection of its own technical system, and the key technologies have reached the international leading level.

③ It is divided into 1-5 grades, and the larger the number, the higher the basic commonality. Among them, level 1 represents the key technology is only the unique technology of the production object in this link. Level 2 represents that key technologies are applicable to this subdivision. Level 3 means that key technologies are applicable to this industry. Level 4 means that key technologies are applicable to most industries. Level 5 represents that key technologies are widely applicable to various industries.

④ It is divided into 1-5 grades. The larger the number, the greater the gap and the difficulty of catching up. Among them, the level of level 1 representatives is basically the same as that of foreign countries. There is a gap of 1-3 years between the level of level 2 representatives and that of foreign countries. There is a gap of 3-5 years between the level of level 3 representatives and that of foreign countries. There is a gap of 5-10 years between the level of level 4 delegates and that of foreign countries. There is a gap of more than 10 years between the level of level 5 representatives and that of foreign countries.

Main characteristic indicators: describe the technical indicators that can be compared at home and abroad.

⑤ The technology without independent ability corresponds to level 1 in the overall evaluation of the list of key technologies, indicating that the technology is completely dependent on the outside world and is in the stage of tackling key scientific and technological problems; The technologies to be industrialized correspond to Grade 2-3 in the overall evaluation of the list of key technologies. Grade 2 indicates that the technology has passed the stage of tackling key scientific and technological problems and is in the stage of commercialization and small-batch production of achievements. Grade 3 indicates that the products and technological processes tend to be mature but have not yet completed the industrialization stage. Mature technologies that can be widely popularized correspond to grades 4-5 in the overall evaluation of the list of key technologies. Grade 4 indicates that the technology has been preliminarily matured and can be applied to individual industries, and grade 5 indicates that the technology is advanced and mature and can be widely popularized.

Note:

① It is divided into 1-5 pieces. The more pieces, the higher the overall level. The overall evaluation can be made by combining the gap between domestic and foreign material suppliers, the diversity and stability of material sources, etc.

② It is divided into 1-5 grades, and the greater the number, the greater the gap. Level 1 represents a high market share of domestic materials, which has strong international competitiveness and is in the forefront of the international market share. Level 2 represents a high market share of domestic materials and has certain competitiveness in the world. Level 3 represents that domestic materials are in the "usable" stage and have a certain market share. Level 4 means that the materials are mainly from abroad, and the domestic materials are in the stage of "not easy to use". Level 5 means that there is no relevant material supplier in China, and the degree of control is high.

③ It is divided into 1-5 grades, and the bigger the number, the better the situation. Overall evaluation can be given in combination with diversity and stability. In terms of diversity evaluation, the first-level representative supplier has a single source. The number of level 2 representative suppliers is small, and all of them are foreign suppliers. Level 3 represents a certain number of suppliers, and most of the products are supplied from abroad. Level 4 represents diversified suppliers, some of which are from abroad. Level 5 means that suppliers have diversified sources and have alternatives in extreme cases. In terms of stability, the main suppliers of the first-level representative core products are extremely unstable and highly constrained, which is greatly affected by changes in the international situation. Level 2 represents the unstable suppliers of core products, which are highly controlled and affected by changes in the international situation. Level 3 represents the suppliers of core products with certain stability, and domestic or friendly countries account for a certain proportion. Level 4 represents stable suppliers of core products, mainly domestic or friendly countries. Level 5 represents stable suppliers of core products, mainly domestic suppliers.

Note:

① It is divided into four levels: international leading, international advanced, domestic leading and domestic advanced. It is necessary to fill in the top three enterprises in terms of foreign and domestic share or overall development level respectively.

② It is divided into 1-5 grades, and the bigger the number, the better the situation. Level 1 represents that domestic enterprises have not established cooperative relations or cannot form cooperation due to lack of links; level 2 represents that some upstream and downstream enterprises have established cooperative relations; level 3 represents that upstream and downstream key enterprises have established cooperative relations; level 4 represents that upstream and downstream key links have established extensive cooperative relations and jointly promoted the research and development and industrialization of new technologies and new products; level 5 represents that upstream and downstream enterprises have closely cooperated and collaborative innovations have been widely applied, forming an overall competitive advantage.

Note:

① It is divided into 1-5★ grades, and the more★, the higher the overall level, which needs to be comprehensively analyzed in combination with the evaluation grades of other columns in this table.

② It is divided into 1-5 grades, and the higher the number, the higher the maturity. Level 1 represents that there are no related design and development tools in China. Level 2 means that there are related design and development tools in China, but the autonomy rate of tools is low. Level 3 means that there are relevant design and research tools in China, with certain independent intellectual property rights, and a certain range of promotion and application is carried out. The R&D tools designed by Level 4 representatives take independent intellectual property rights as the core, and the application ecological environment is relatively perfect. Level 5 representatives have independent intellectual property rights and strong international competitiveness.

③ It is divided into 1-5 grades. The larger the number, the greater the gap and the difficulty of catching up. Among them, there is basically no difference in the level of level 1 representatives. There is a gap of 1-3 years between the level of level 2 representatives and that of foreign countries. There is a gap of 3-5 years between the level of level 3 representatives and that of foreign countries. There is a gap of 5-10 years between the level of level 4 delegates and that of foreign countries. There is a gap of more than 10 years between the level of level 5 representatives and foreign countries, so it is very difficult to catch up.

Note:

① It is divided into 1-5★ grades, and the more★, the higher the overall level. Overall evaluation combined with domestic manufacturing equipment capabilities and gaps and other factors for overall comprehensive analysis.

② It is divided into 1-5 grades. The larger the number, the greater the gap and the difficulty of catching up. Among them, there is basically no difference in the level of level 1 representatives. There is a gap of 1-3 years between the level of level 2 representatives and that of foreign countries. There is a gap of 3-5 years between the level of level 3 representatives and that of foreign countries. There is a gap of 5-10 years between the level of level 4 delegates and that of foreign countries. There is a gap of more than 10 years between the level of level 5 representatives and foreign countries, so it is very difficult to catch up.

Static breakthrough period: the shortest time required for domestic production of products of the same level as those of foreign countries.

Note:

According to the concept of "quality is determined by R&D and design, realized by manufacturing and guaranteed by inspection and testing", quality runs through the whole life cycle of products and requires various quality engineering technologies. Among them, quality design technology is related design control technology around quality characteristics in the design process of products or manufacturing. Such as: design parameter optimization technology, reliability design technology and so on. Manufacturing process quality control technology is a related control technology around product quality characteristics in the process of product processing and manufacturing. Such as: on-line measurement control technology, equipment stability assurance technology, etc. Detection and test technology is related to the measurement, inspection and test of product quality characteristics. Such as calibration technology. Quality assurance technology: It refers to the technology related to product quality control in order to ensure users’ continuous use requirements and subsequent quality improvement during product delivery and operation. Such as: Operation and Maintenance Task Analysis Technology (OMTA), Fault Reporting, Analysis and Corrective Action System (FRACAS), etc.

① It is divided into 1-5★ grades, and the more★, the higher the overall level. 1★ represents the lack of quality engineering technology, and there is no relevant quality engineering technology institution in China. 2★ represents weak quality engineering technology and lack of authoritative organization. Level 3★ means that there is a gap in quality engineering technology, and it has a well-known quality engineering technology institution. 4★ It represents that there is a gap in some domestic quality engineering technologies, and it has internationally renowned quality engineering technology institutions. 5★ represents that quality engineering technology is at the same level with foreign countries, and it has international advanced quality engineering technology institutions.

② It is divided into 1-5 grades. The larger the number, the greater the gap and the difficulty of catching up. Among them, there is basically no difference in the level of level 1 representatives. There is a gap of 1-3 years between the level of level 2 representatives and that of foreign countries. There is a gap of 3-5 years between the level of level 3 representatives and that of foreign countries. There is a gap of 5-10 years between the level of level 4 delegates and that of foreign countries. There is a gap of more than 10 years between the level of level 5 representatives and foreign countries, so it is very difficult to catch up.

Note:

Standard categories include: international standards, regional standards, national standards, industry standards, group standards and enterprise-led factual standards.

① It is divided into 1-5★ grades, and the more★, the higher the overall level. One ★ represents a serious lack of domestic standards in this field, no independent standards and lack of application, the standards are subject to people and difficult to break through, the right to speak technology is seriously lacking, and the necessary patents for standards are held by foreign enterprises. Two ★ represent the lack of domestic standards in this field, the insufficient number and application of independent standards, the insufficient matching between independent standards and the current level of industrial development, and the existence of many new technologies and products that have not been covered. China has adopted international standards, but it lacks the right to speak in technology. 3 ★ represents that there are a certain number of independent standards in China, but the standard system is not perfect, the applicability of independent standards basically matches the current industrial development level, the digitalization of standards has begun to advance, and there are some new technologies and products that have not been covered. The implementation of standards in this field is good, and the standards have been adopted by certain policies in terms of market access, supervision after the event, etc. China has participated in the formulation of international standards in this field and formed a certain technical discourse right in some sub-fields. 4 ★ Represents that domestic standards in this field are relatively complete, and there is a mature standard system. Independent standards and standards are widely used digitally, which has played a great role in promoting industrial development. The implementation of standards in this field by enterprises is very good, and standards are widely publicized and trained. Standards have more policy acceptance in market access, supervision after the event, etc., and domestic enterprises actively participate in international standardization activities in this field.And formed a greater technical discourse power. Five stars ★ represent that the standards in this field are complete and sufficient, the standard system is sound and forward-looking, and the independent standards and standards are widely used digitally, which has played an important role in promoting industrial development. Enterprises have achieved remarkable results in implementing the standards in this field, with a high compliance rate. They have organized extensive standards publicity and training, and the standards have been widely adopted by policies in terms of market access and supervision afterwards, and have established a leading position in international standardization in this field.

Note:

① It is divided into 1-5★ grades, and the more★, the higher the overall level. The overall evaluation combines the gap between domestic and foreign major service providers, the level of digital development and the level of green development to make a comprehensive analysis.

② It is divided into 1-5 grades, and the higher the number, the higher the level of digital development. Level 1 representatives do not have the relevant digital transformation and development capabilities. The second-level representative part adopted automation technology and information technology to transform and upgrade the production activities, and initially realized the data sharing of the business. Level 3 represents the integration of the equipment and systems involved to realize cross-link data sharing. Level 4 fully excavates and applies the data of personnel, resources and manufacturing in the manufacturing process through digital means, and the production efficiency and product quality are obviously improved. Level 5 represents the iterative upgrading of the industry based on digital technology, efficient coordination of the industrial chain, and accelerated formation of new models and new formats.

③ It is divided into 1-5 grades, and the higher the number, the higher the level of green development. Level 1 represents high energy consumption level of products, weak pollutant treatment capacity and generally weak awareness of green development. Level 2 represents a high level of energy consumption, a weak ability to deal with pollutants, and a weak ability to serve green manufacturing. Level 3 delegates have established a green development mechanism, initially carried out energy conservation, pollutant prevention and control, and formed a number of green technology/solution service providers. Level 4 represents that green and low-carbon technologies have been expanded and applied, energy consumption level and carbon emission intensity have been steadily reduced, and the green technology/solution service system is relatively perfect. Level 5 represents a low energy consumption level, achieving peak carbon dioxide emissions, and improving the green technology/solution service provider system.

④ It is divided into 1-5 grades, and the larger the number, the higher the maturity of the supporting facilities. Level 1 representatives have no relevant public service platform at present. Level 2 representatives have relevant public service platforms, and their service capabilities are single. Level 3 representatives have relevant public service platforms and provide some necessary public service projects. The four-level representative service platform has common services such as information service, financing service, technological innovation service, entrepreneurship service, training service, management consulting service, market development and legal service. The Level-5 representative platform focuses on industrial characteristics and application requirements, and has established complete services including specialized information services, financing services, technological innovation services, entrepreneurial services, training services, management consulting services, market development, and legal services.

Note:

① It is divided into R&D design software, business management software, production control software and basic general software.

② It is divided into 1-5★ grades, and the more★, the higher the overall level. The overall evaluation includes the comprehensive evaluation of the strength comparison, gap and catch-up difficulty of domestic and foreign enterprises.

③ It is divided into 1-5 grades. The larger the number, the greater the gap and the difficulty of catching up. Among them, there is basically no difference in the level of level 1 representatives. There is a gap of 1-3 years between the level of level 2 representatives and that of foreign countries. There is a gap of 3-5 years between the level of level 3 representatives and that of foreign countries. There is a gap of 5-10 years between the level of level 4 delegates and that of foreign countries. There is a gap of more than 10 years between the level of level 5 representatives and foreign countries, so it is very difficult to catch up.